Overview

Flanged BDV

They are also used in refineries at various units like Crude Distillation Unit (CDU), Fluid Catalytic Cracking Unit (FCCU), Hydrocracking Unit, Reforming Unit, Sulphur Recovery Unit (SRU), etc. to remove impurities and contaminants.

Get a custom quote for energy-efficient boiler blowdown valves that save you money.

Applications

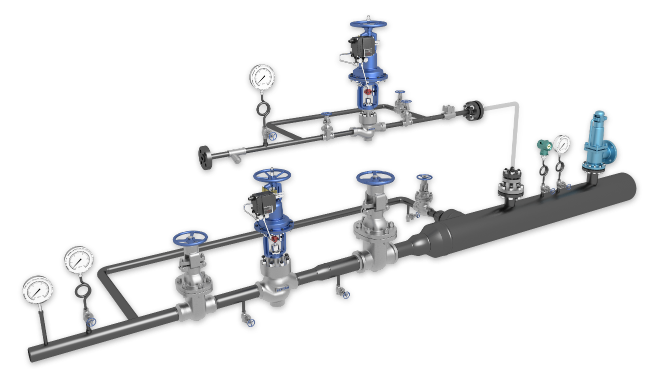

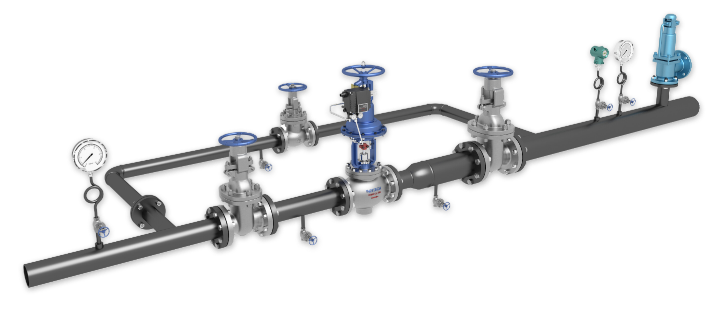

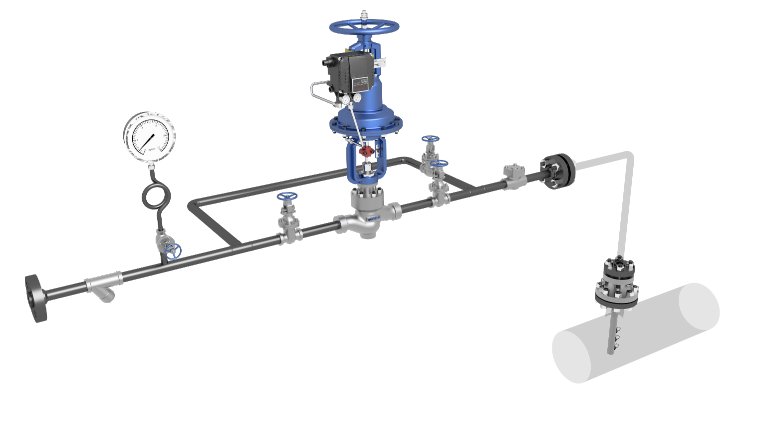

Continuous Blowdown Valve (CBD):

IndiTech’s offerings of Continuous Blowdown Valves include:

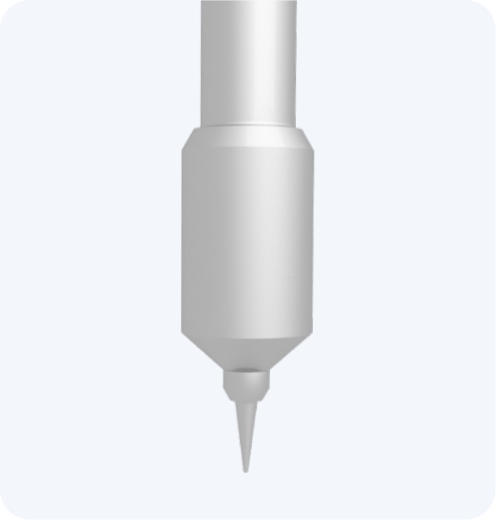

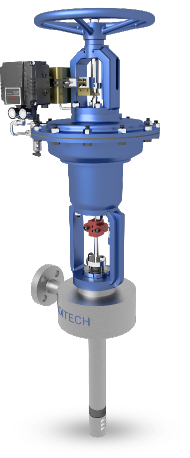

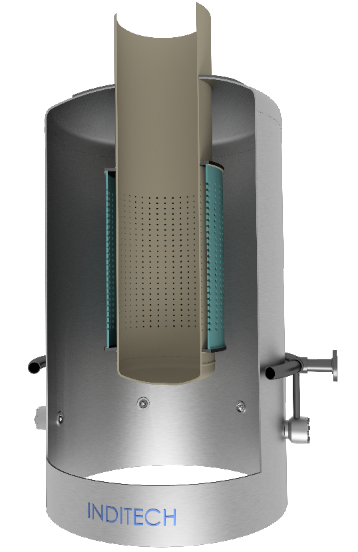

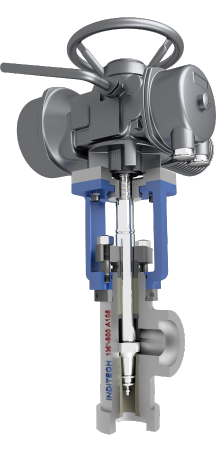

1) An Angle Type Continuous Blowdown Valve features a needle-shaped trim within a venturi diffuser. This diffuser offers ample space for high-velocity flashing water, preventing choked flow.

2) Regulating Lever Continuous Blowdown valve with straight pattern design.

Intermittent Blowdown Valve (IBD):

IndiTech’s offerings of Intermittent Blowdown Valves include:

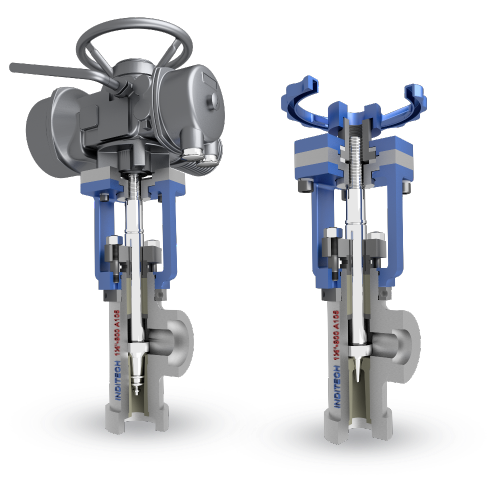

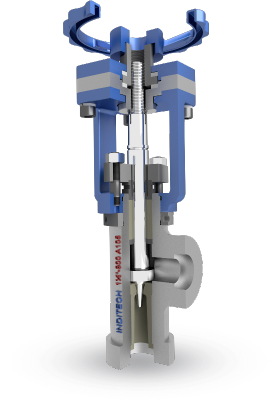

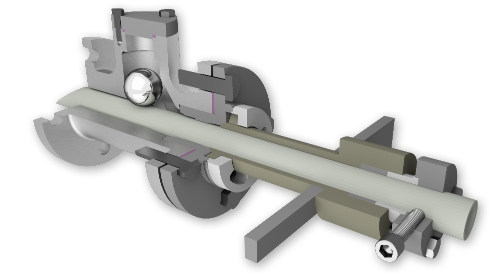

1) An Angle Type Intermittent Blowdown Valve featuring a multi-step throttling plug that allows to carry out dual functions – blowdown in the open position and sealing in the closed position. Since the total pressure drop gets divided across each stage, the area for sealing is separate from the throttling area, which minimises erosion and ensures a leak-proof performance even after extensive use.

2) A Lever-Operated quick-action blowdown valve, which, when operated, creates a suction effect in the boiler, thereby causing the thicker sludge deposits to be flushed out. The valve then closes automatically as soon as the lever is let loose. This fast opening and closing ensures minimum loss of boiler feed water.

Technical Data

320

ANSINPS 1 To NPS 3 (DN25 To DN80)

ANSI CL300 To CL2500

A105; A182 F11/F22/F91/F316

Flanged/Socket Weld/Butt Weld

Class IV/Class V

Motorised/Lever Operated/Manual

Features

- Forged body suited for severe service blowdown duty due to excellent body integrity and strength as compared to cast bodies

- Stellited plug-spindle & seat for resistance against erosion and wire drawing, avoiding premature valve failure

- Integral plug-spindle for vibration and chatter-free operation

- Extra-long gland packing for tight seal at high temperatures

Specific Advantages of IndiTech Angle Type Blowdown Valves

- Angle design ensures self-draining of the blowdown valve

- Single-step trim with venturi diffuser for continuous operation and multi-step pressure-reducing trim for Intermittent operation valve

- Pressure seal bonnet for high-pressure applications

- Compact or Heavy-Duty design options available

Specific Advantages of IndiTech Lever-Operated Blowdown Valves

- Fast opening and closing facilitated by lever & spring-return mechanism

- Pin for locking valve in closed position (lever up) or in open position for draining boiler (lever down)