Overview

PCI Injection Lance Replacement made Safe & Easy

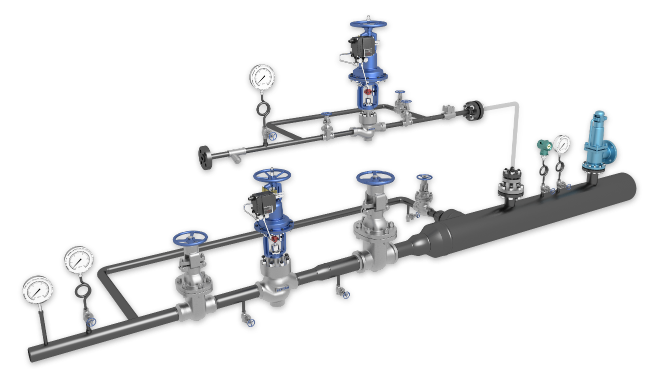

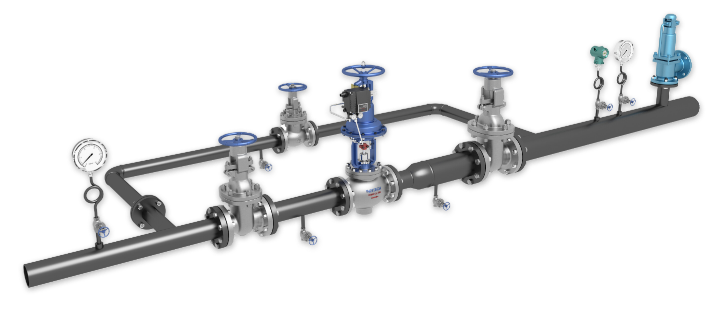

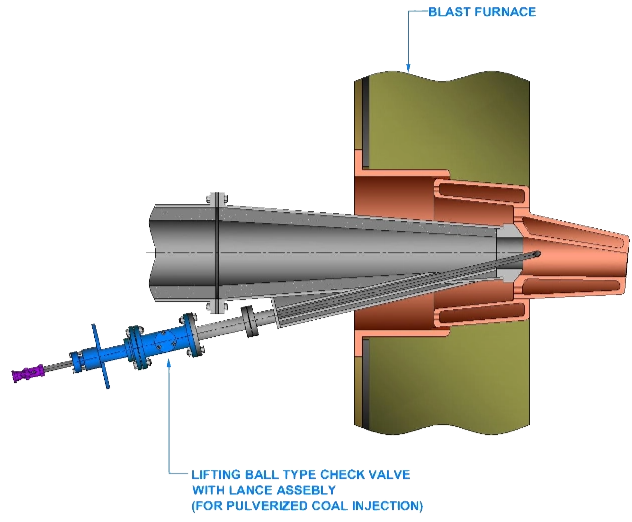

The blast furnace is the heart of any integrated steel plant. It is responsible for producing the molten iron that is the primary input for steelmaking. In recent times, Pulverized Coal Injection (PCI) / Coal Dust Injection (CDI) has transformed how blast furnaces operate. PCI offers various advantages, such as increased blast furnace productivity and reduced coke consumption, which translates to substantial cost savings. Also, by partially replacing coke, a more carbon-intensive fuel, PCI helps reduce greenhouse gas emissions.

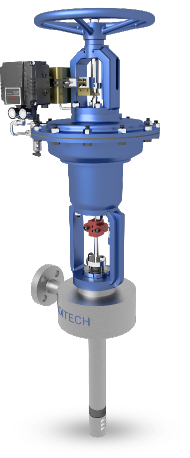

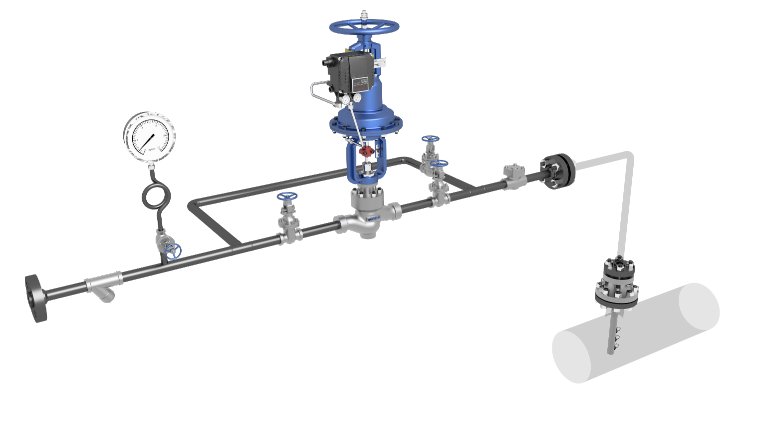

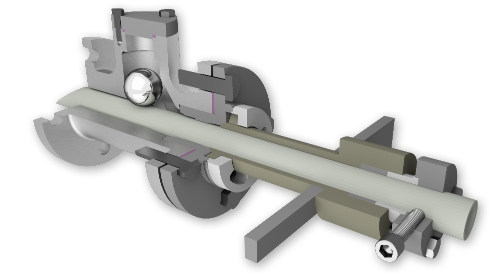

In PCI, finely ground coal is injected directly into the blast furnace through injection lances. Harsh operating conditions inside the blast furnace, where temperatures reach as high as 1200°C, cause these injection lances to experience significant wear and tear, requiring periodic replacement. The critical function of insertion & removal of injection lances is facilitated by employing Non-Return Valves (NRV) mounted on each Tuyere.

Safeguard your lance replacement operation with our Ball Check Valves.

Application Criticality

Common challenges encountered during injection lance replacement:

- Possibility of serious accidents due to leakage of hot blast gases at ~1200°C

- Unsafe operation due to jamming/failure of internal components of NRV

- Loss of productivity due to the requirement of BF shutdown/downtime for injection lance replacement

- Difficulty in fast turnaround due to heavy & cumbersome equipment

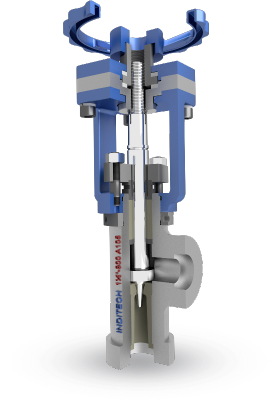

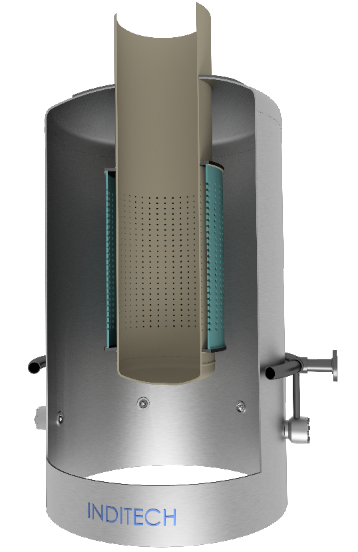

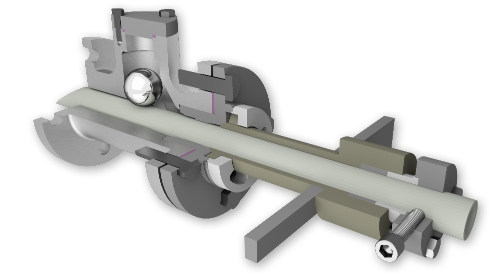

IndiTech offers a special lifting ball type check valve (also known as bullet valve) to solve the challenges mentioned above. Its simple design, tight sealing and high performance make it ideal for this critical application.

Customer References

Client Testimonials

These valves have facilitated online insertion and removal of the Injection Lance, without need for Blast Furnace shutdown, thereby significantly reducing downtime of Blast Furnace.

General Manager, SLR Metaliks, Karnataka

Overall performance of the valve is good. Workmen are happy with the design due to ease in removal & fitment.

Manager, Vedanta Sesa Goa

Technical Data

INDITECH SERIES

330

VALVE SIZE

DN40 (suitable for lance OD ½”)

DN50 (suitable for lance OD ½”, ¾”, 1”)

PRESSURE RATING

CL150/CL300/PN40

END CONNECTIONS

Flanged

BODY MATERIAL

A216 WCB

BALL MATERIAL

SS 316

DESIGN STANDARD

ASME B16.34

CONFIGURATIONS

- Ball Check Valve (NRV) only

- Complete Injection Lance Assembly

- Injection Lance only

Features

- Proven solution that is 100% safe for operators

- Facilitates online replacement of Injection Lance without need for BF shutdown

- Precise manufacturing that ensures immediate closure of NRV as soon as Injection Lance is removed

- Simple yet effective design, which makes it very easy to use & operate

- Precision machined sealing surfaces for consistent leak-proof performance

- Successful track record since 2005

IndiTech Advantage

We can provide completely customised solutions to suit your existing space & design constraints